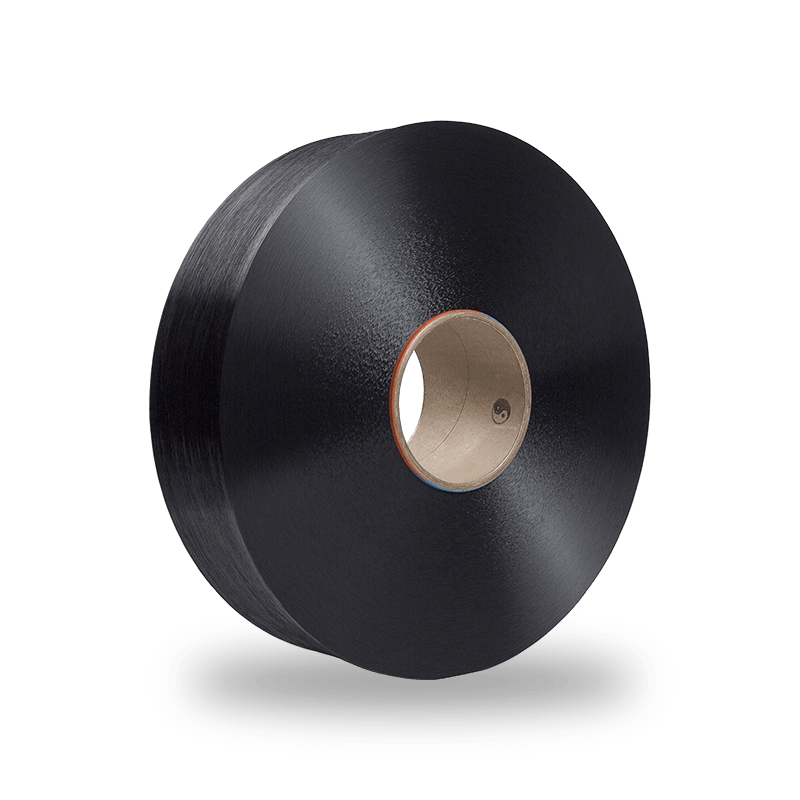

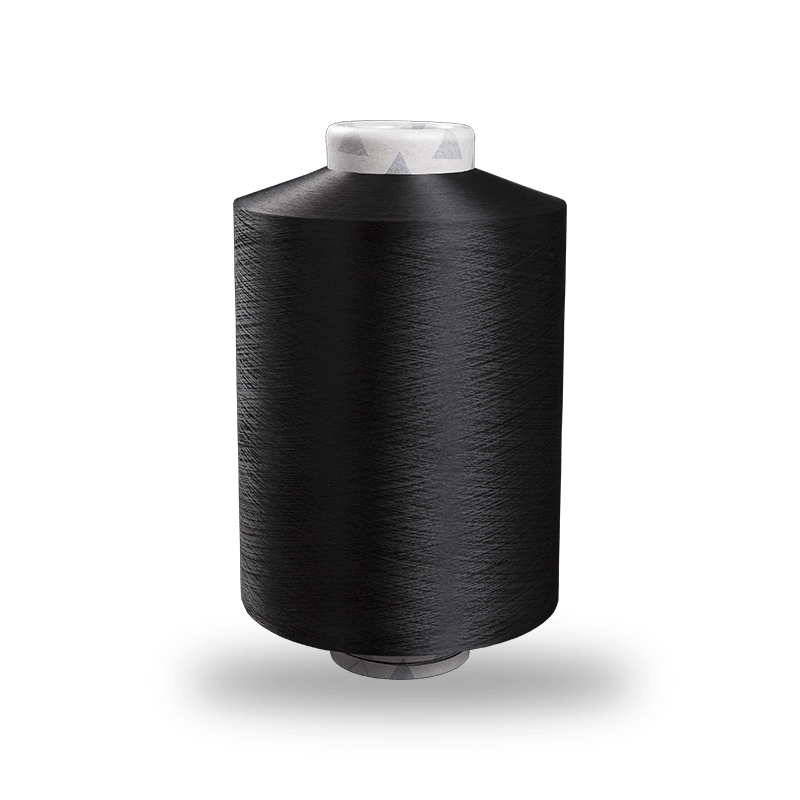

In recent years, the textile industry has been under increasing pressure to address environmental concerns associated with synthetic fibers like Nylon 6 FDY (Fully Drawn Yarn). As consumers become more conscious of the environmental impact of their purchases, manufacturers are exploring ways to make Nylon 6 FDY production more sustainable and environmentally friendly.

Recycling Initiatives: Closing the Loop

The significant efforts to enhance the sustainability of Nylon 6 FDY production involves embracing recycling initiatives. Companies are investing in technologies to collect post-consumer nylon waste, including discarded garments and industrial scraps, and transform them into recycled nylon (rPET). By incorporating recycled materials into Nylon 6 FDY production, the industry reduces its reliance on virgin resources and minimizes waste sent to landfill

Energy and Resource Efficiency: Reducing Footprint

Efforts to reduce energy and water consumption are central to sustainable Nylon 6 FDY production. Manufacturers are implementing energy-efficient technologies and processes, optimizing equipment and machinery to minimize energy usage. Additionally, water recycling and reuse initiatives help conserve this precious resource, further reducing the environmental footprint of Nylon 6 FDY production.

Bio-Based Alternatives: Greening the Supply Chain

Innovations in feedstocks are reshaping the landscape of Nylon 6 FDY production. Research into bio-based alternatives aims to replace fossil fuel-derived raw materials with renewable sources. By leveraging bio-based feedstocks, such as plant-based polymers, the industry reduces its carbon footprint and lessens dependency on finite resources, contributing to a more sustainable supply chain.

Chemical Innovation: Toward Greener Processes

Advancements in chemical processes play a crucial role in improving the environmental profile of Nylon 6 FDY production. Innovations in catalysts and reaction conditions enable the development of greener manufacturing processes. This includes the exploration of eco-friendly solvents, the reduction of hazardous chemicals, and the optimization of reaction conditions to minimize waste and emissions, fostering a cleaner production process.

Standards and Certifications: Driving Accountability

To guide sustainable practices in Nylon 6 FDY production, industry organizations and certification bodies have established sustainability standards and certifications. These frameworks encompass criteria related to resource efficiency, environmental impact, and social responsibility throughout the supply chain. By adhering to these standards, manufacturers demonstrate their commitment to sustainability and accountability in Nylon 6 FDY production.

The textile industry is witnessing a paradigm shift toward sustainability, and Nylon 6 FDY production is no exception. Through recycling initiatives, energy and resource efficiency measures, adoption of bio-based alternatives, chemical innovation, and adherence to sustainability standards, efforts are underway to make Nylon 6 FDY production more sustainable and environmentally friendly. As these initiatives continue to evolve, they pave the way for a greener future in synthetic fiber manufacturing.

English

English 中文简体

中文简体 Español

Español عربى

عربى