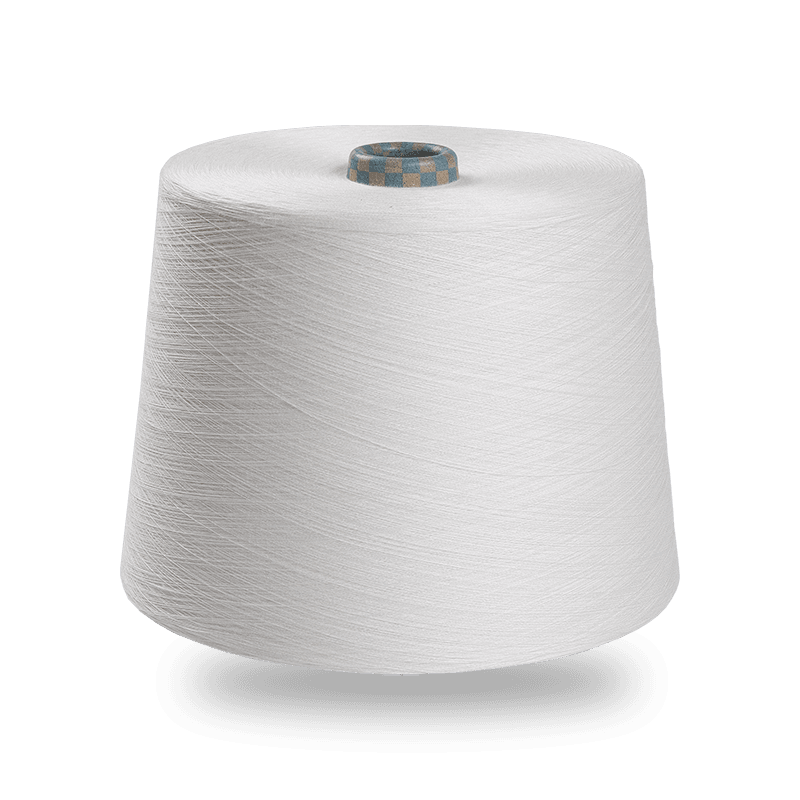

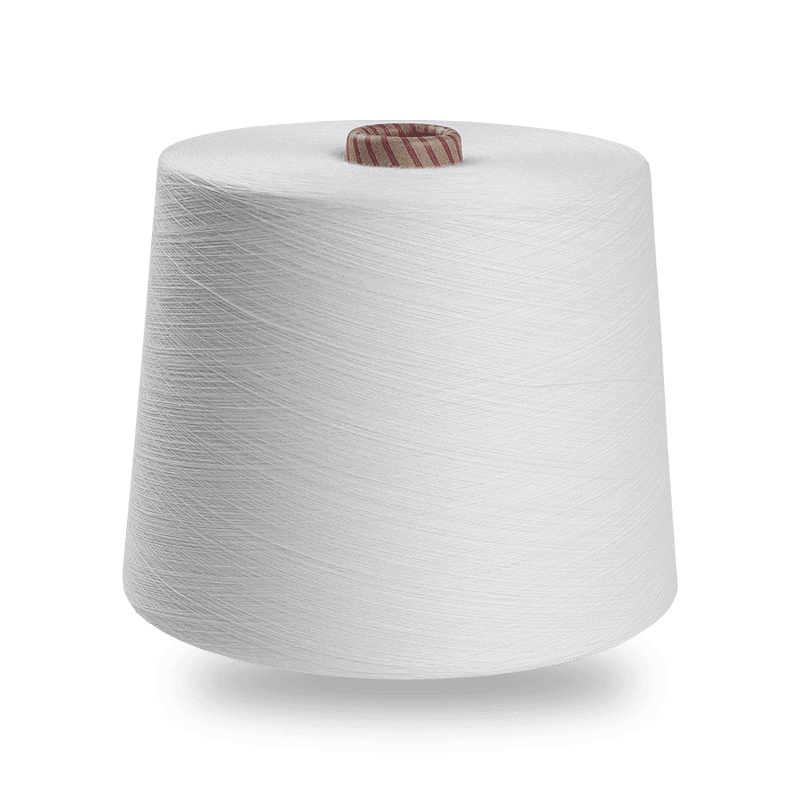

Customization is instrumental in the textile industry, particularly with Siro spun yarn, renowned for its distinctive spinning technique and fiber blends. By modifying yarn attributes, manufacturers can profoundly affect not only the physical properties of the yarn but also its applicability across a multitude of sectors. Siro spun yarn, crafted by stretching and twisting rovings into a ply-like format, presents a rich spectrum of customization possibilities, facilitating blends of materials such as viscose, polyester, and acrylic in varying proportions. This adaptability paves the way for creating yarns tailored to specific performance criteria, whether it be strength, softness, or breathability.

The impactful aspects of customization is fiber blending. The capability to combine diverse materials in exact ratios empowers manufacturers to produce yarns that possess the desired texture, resilience, and visual allure. For example, a blend of viscose with polyester yields a yarn that retains the soft, breathable nature of rayon while significantly enhancing strength and wrinkle resistance. This versatility makes it suitable for a broad range of applications, from lightweight summer apparel to durable fabrics designed for everyday use. Similarly, merging acrylic with viscose results in a yarn that is luxuriously soft yet vibrantly colored, ideal for contemporary fashion textiles.

Furthermore, customization transcends mere fiber composition to encompass factors such as yarn thickness, twist density, and finishing techniques. These elements can profoundly influence the yarn’s performance in various contexts. A tighter twist can amplify strength and abrasion resistance, rendering the yarn suitable for high-wear items like denim or work garments, whereas a looser twist may be preferable for softer textiles, such as shirts or loungewear. Additionally, specialized finishing methods can enhance features like moisture-wicking or anti-pilling, thus expanding the yarn's utility in targeted markets.

The ramifications of these customized yarns are extensive. For manufacturers and designers alike, access to a diverse array of Siro spun yarn options enables swift adaptation to market trends and consumer preferences. As sustainability gains prominence, yarns can be engineered to incorporate recycled fibers, offering an eco-friendly alternative without sacrificing quality. This agility not only confers a competitive advantage to brands but also bolsters their reputation in an industry increasingly driven by innovation and ethical considerations.

The customization of Siro spun yarn profoundly influences both its properties and potential applications. By facilitating tailored blends and specific performance features, manufacturers can produce versatile, high-quality yarns that serve a myriad of industries—from fashion to functional textiles. As the appetite for specialized products continues to expand, the capacity to customize yarn will undeniably be pivotal in shaping the future landscape of textile production.

English

English 中文简体

中文简体 Español

Español عربى

عربى