Nylon fiber fabrics can be divided into three categories: pure spinning, blended spinning and interwoven fabrics, and each category contains many varieties.

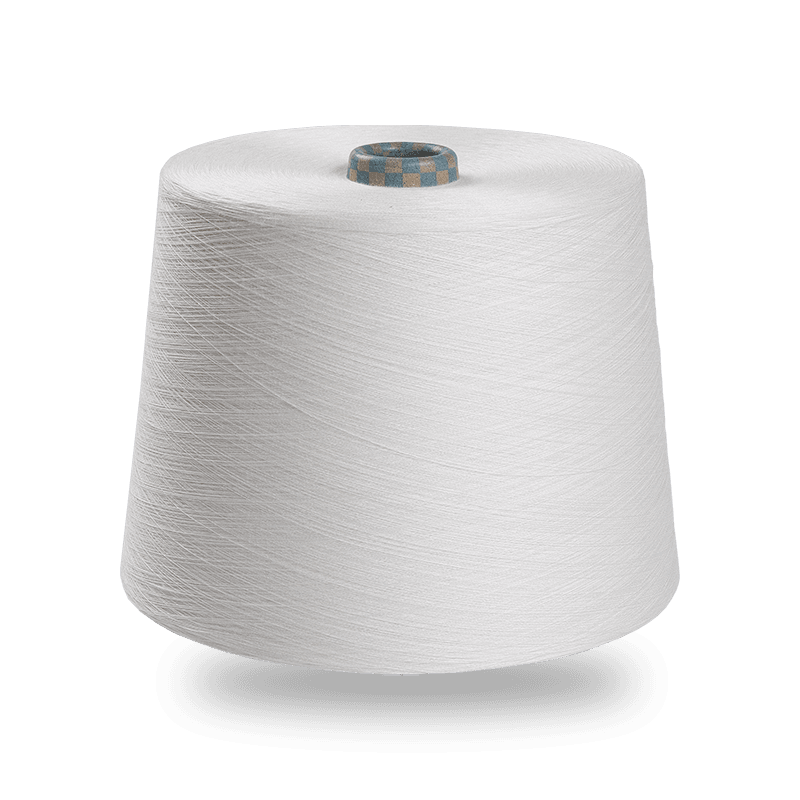

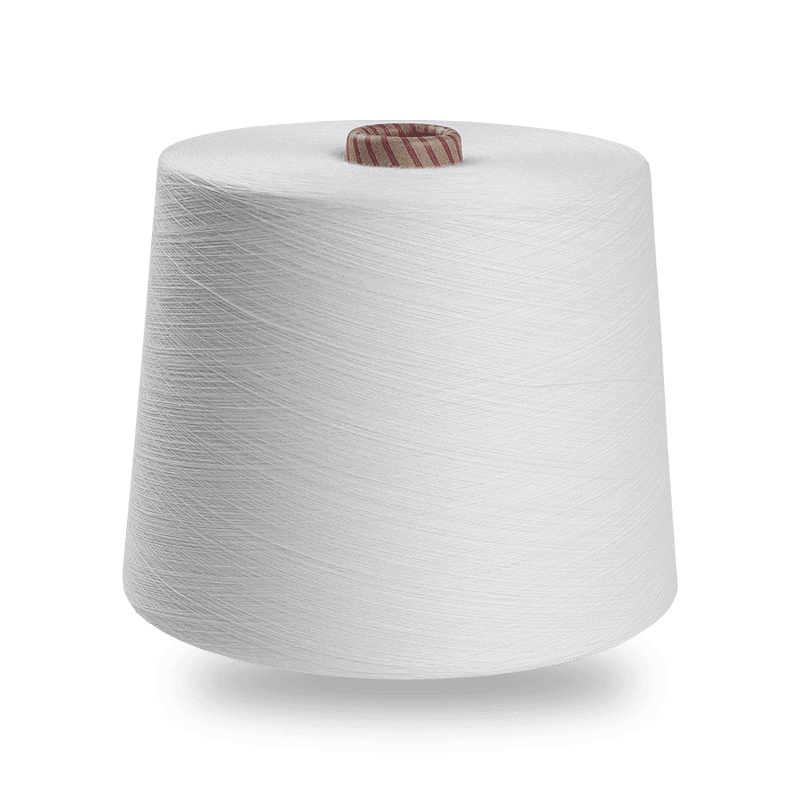

1. Nylon pure textiles Various fabrics, such as nylon taffeta, nylon crepe, etc., are woven from nylon silk. Because it is woven with nylon filament, it has the characteristics of smooth hand feeling, firmness and durability, and moderate price. It also has the shortcomings that the fabric is easy to wrinkle and is not easy to recover. Nylon taffeta is mostly used for light clothing, down jackets or raincoat cloth, while nylon crepe is suitable for summer dresses, spring and autumn sweaters, etc.

2. Nylon blended and interwoven fabrics The fabrics obtained by blending or interweaving nylon filaments or short fibers with other fibers have the characteristics and strengths of each fiber. For example, viscose/nylon gabardine is made by blending 15% nylon and 85% viscose into yarn. It has the warp density twice as large as the weft density, and the cloth has the characteristics of thick texture, toughness and durability. The disadvantage is that it is poor in elasticity and easy to wear. Wrinkles, wet strength decreases, and it is easy to sag when worn. In addition, there are sticky/jinfanliding, sticky/brocade/wool tweed and other varieties, all of which are commonly used fabrics.

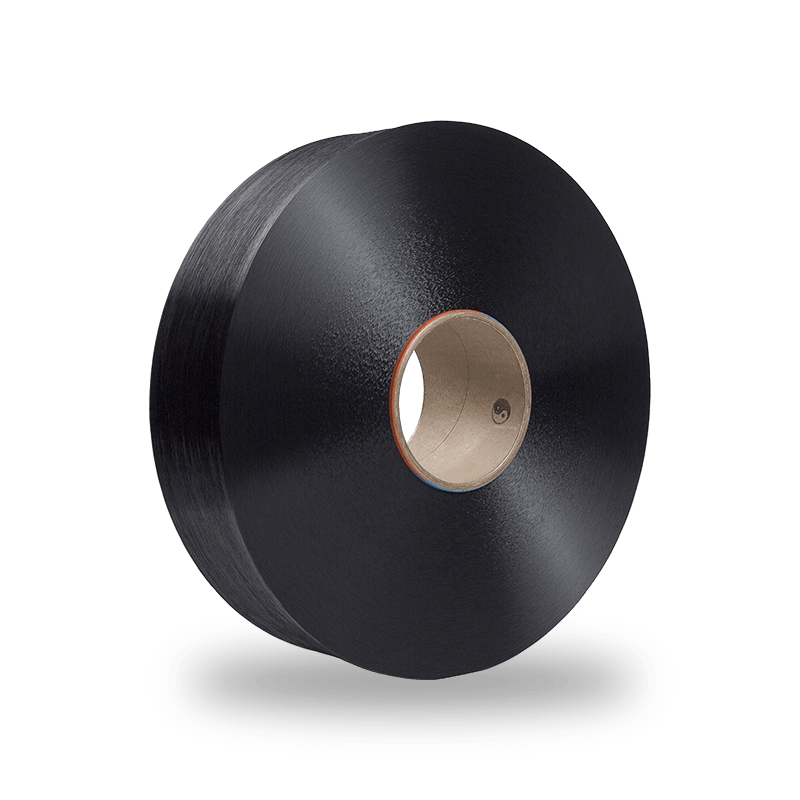

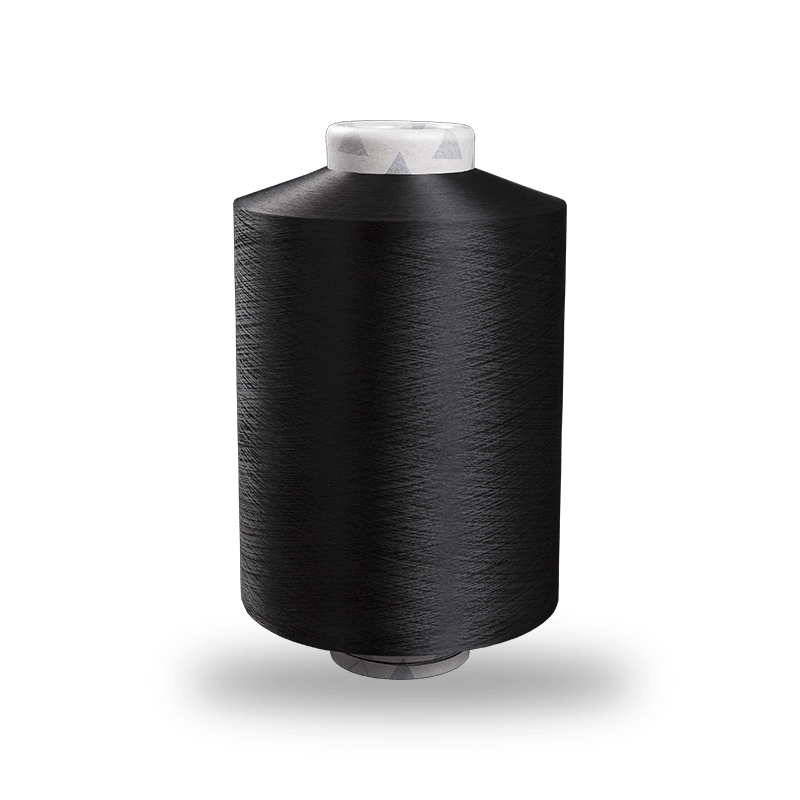

The most common nylon products on the market are nylon 6 and nylon 66.

Nylon 6: The full name is polycaprolactam fiber, which is polymerized by caprolactam.

Nylon 66: The full name is polyhexamethylene adipamide fiber, which is polymerized by adipic acid and hexamethylene diamine.

The common characteristics of nylon 6 and nylon 66: poor light resistance, under long-term sunlight and ultraviolet light, the strength decreases and the color becomes yellow; its heat resistance is not good enough, and it changes after 5 hours at 150°C. Yellow, the strength and elongation decrease significantly, and the shrinkage rate increases. Nylon 6, 66 filaments have good low temperature resistance, and their resilience does not change much when the temperature is below minus 70°C. Its direct current conductivity is very low, and it is easy to generate static electricity due to friction during processing. Its conductivity increases with the increase of moisture absorption, and increases with the increase of humidity according to the law of exponential function. Nylon 6, 66 filaments have strong resistance to microbial action, and their resistance to microbial action in silt water or alkali is second only to that of chlorinated fiber. In terms of chemical properties, nylon 6, 66 filaments have alkali resistance and reducing agent resistance, but they have poor performance in acid resistance and oxidant resistance.

English

English 中文简体

中文简体 Español

Español عربى

عربى