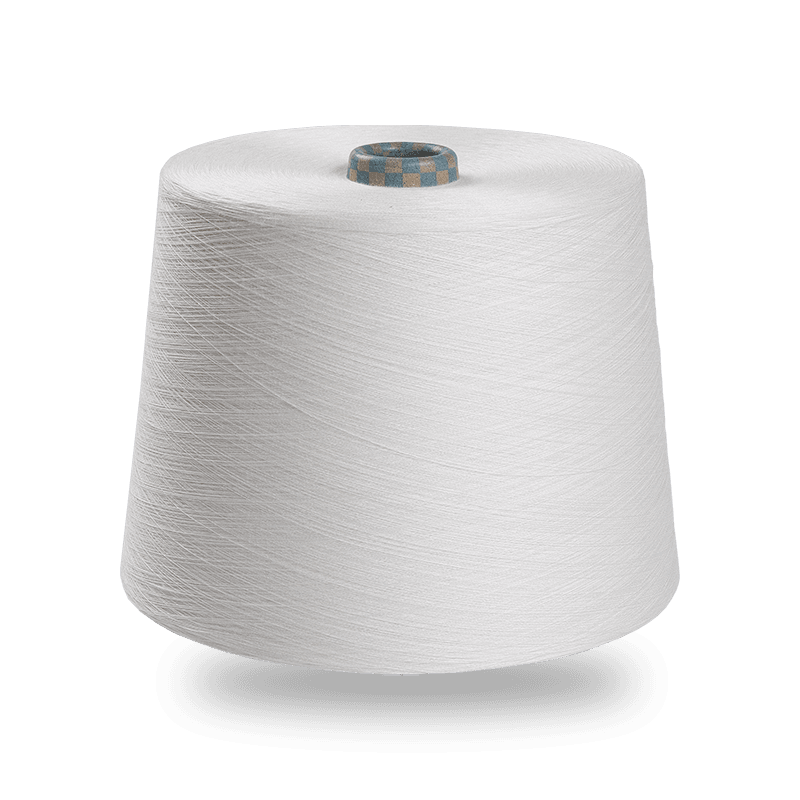

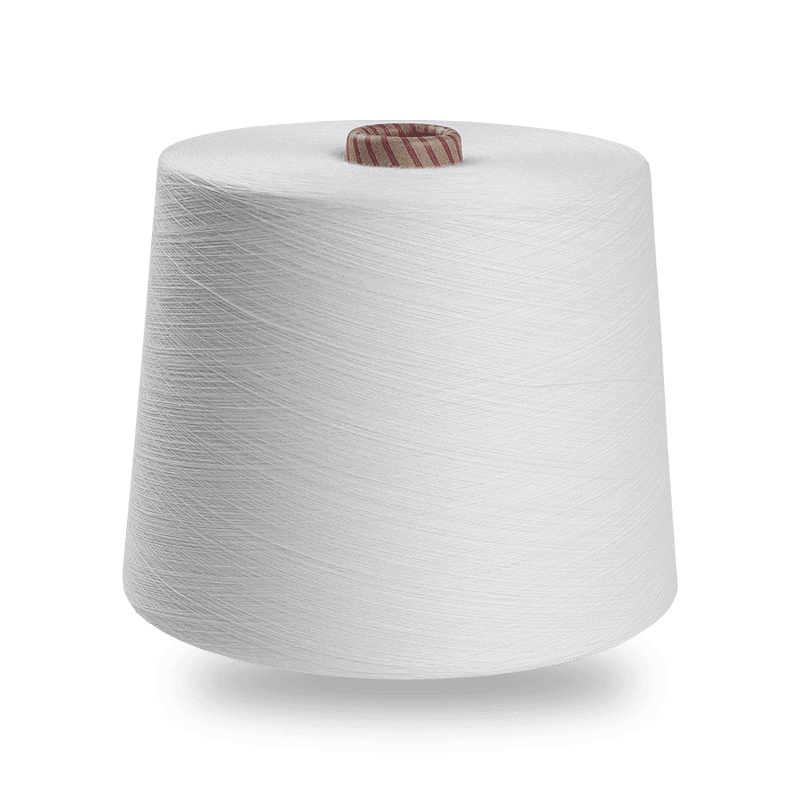

Hairiness refers to the small, protruding fibers that extend from the main body of the yarn. This characteristic can significantly influence the texture, appearance, and performance of the fabric made from these yarns. In the case of Siro spun yarns, the level of hairiness is notably lower compared to other spinning methods, and this difference plays a crucial role in shaping the final fabric product.

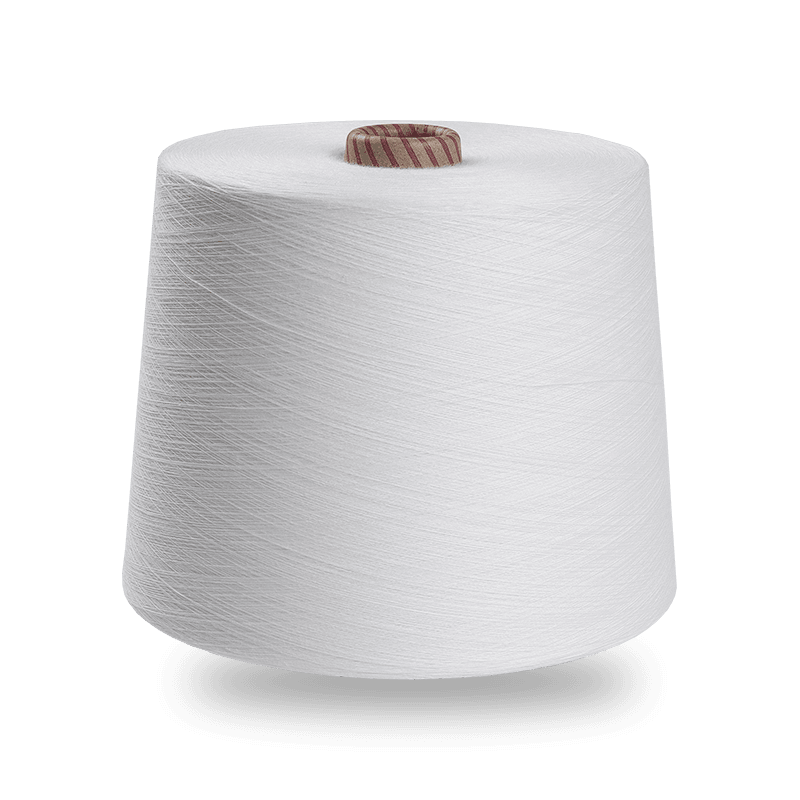

Siro spinning, also known as double twist spinning, involves twisting two rovings together into a single ply-like yarn, which is then wound onto a bobbin. This process is designed to improve yarn smoothness and uniformity. As a result, the yarn produced by this method typically exhibits less hairiness than yarns spun by conventional ring spinning. The reason for this reduction in hairiness lies in the mechanics of the Siro spinning technique, which minimizes the formation of loose, stray fibers that can create a more rough texture. The tightly twisted nature of Siro spun yarns helps to lock fibers in place, leading to a cleaner and more polished appearance compared to other yarns.

The reduced hairiness in Siro spun yarns has a significant impact on fabric appearance. Fabrics woven or knitted from Siro spun yarns tend to have a smoother, more refined surface. This makes them particularly appealing for high-end apparel, such as shirts, denim, and lightweight summer fabrics, where the texture and softness of the material are highly valued. Fabrics made from Siro spun yarns are often more aesthetically pleasing due to their uniform surface, with fewer visible fibers sticking out. This results in a cleaner, more sophisticated look that enhances the overall visual appeal of the garment. In contrast, yarns with higher levels of hairiness, such as those produced by ring spinning, can sometimes create a fuzzier, less polished appearance, which may not be desirable for certain types of fabric.

Beyond aesthetics, the reduced hairiness of Siro spun yarns also plays a role in fabric functionality. Hairiness can have several practical consequences, such as increased pilling, reduced fabric durability, and more frequent maintenance. Fabrics with excessive hairiness tend to develop small balls of fibers, known as pills, on the surface, which detract from the overall appearance and feel of the fabric. This issue is particularly noticeable in fabrics used for garments that are subjected to frequent wear, such as sweaters and activewear. The low hairiness of Siro spun yarns helps minimize pilling, leading to a cleaner, more durable fabric that maintains its appearance over time.

Furthermore, the smoother surface of Siro spun yarns contributes to superior fabric softness and breathability. Fabrics made from these yarns are typically softer to the touch, providing a more comfortable wearing experience. This is particularly important in garments intended for warmer weather, where comfort and breathability are key considerations. The smooth texture of Siro spun yarns also enhances the overall drape of the fabric, giving it a more fluid and elegant movement, which is highly desirable in lightweight fabrics such as those used for summer dresses or shirts.

Another practical advantage of the low hairiness of Siro spun yarns is their improved abrasion resistance. The tightly twisted fibers in Siro spun yarns are less likely to fray or break, which contributes to better overall fabric durability. This characteristic makes Siro spun yarns ideal for fabrics that need to withstand wear and tear, such as workwear or heavy-duty textiles. The lower hairiness also means that the yarns are less likely to shed fibers, which helps maintain the integrity of the fabric throughout its lifespan.

These yarns create smoother, more uniform fabrics that are visually appealing and soft to the touch, while also being more durable and resistant to pilling. The lack of excess hairiness enhances the overall quality of the fabric, making it ideal for a wide range of textile applications, from everyday clothing to high-end garments. As such, Siro spun yarns stand out as a versatile and superior choice for manufacturers looking to create high-quality, durable, and aesthetically pleasing fabrics.

English

English 中文简体

中文简体 Español

Español عربى

عربى