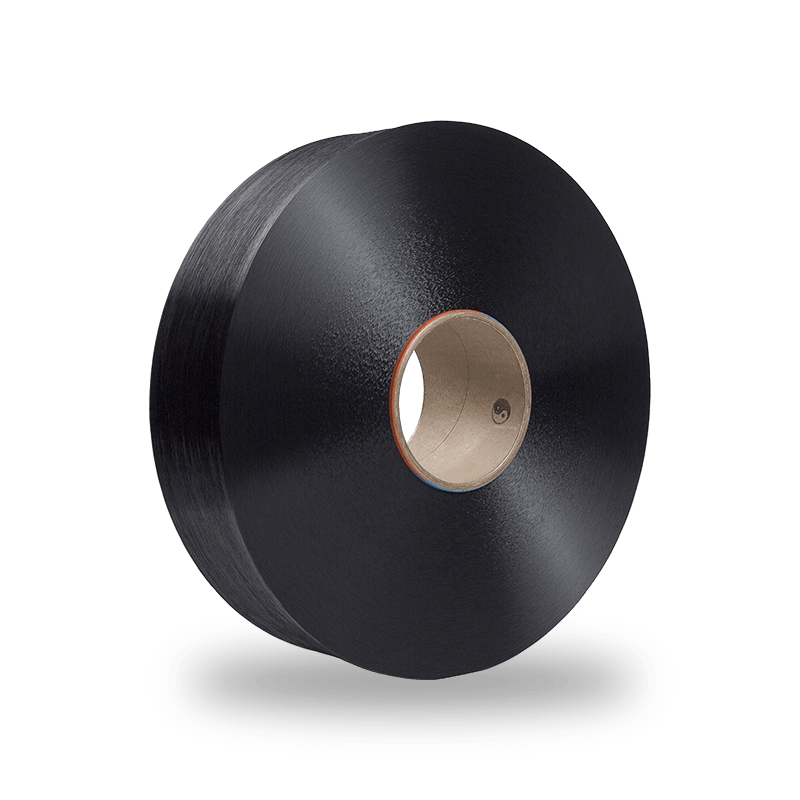

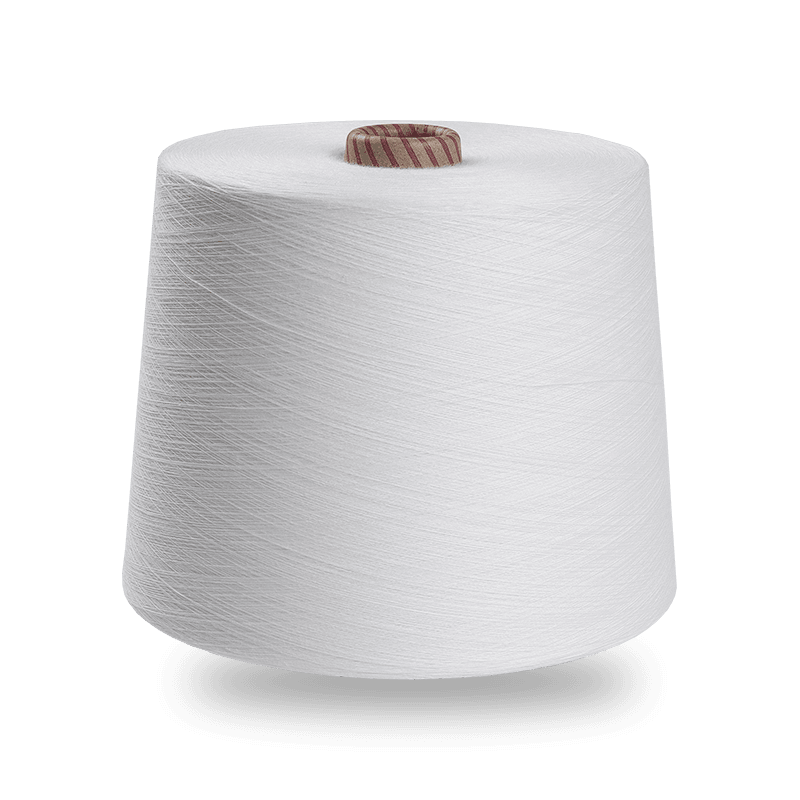

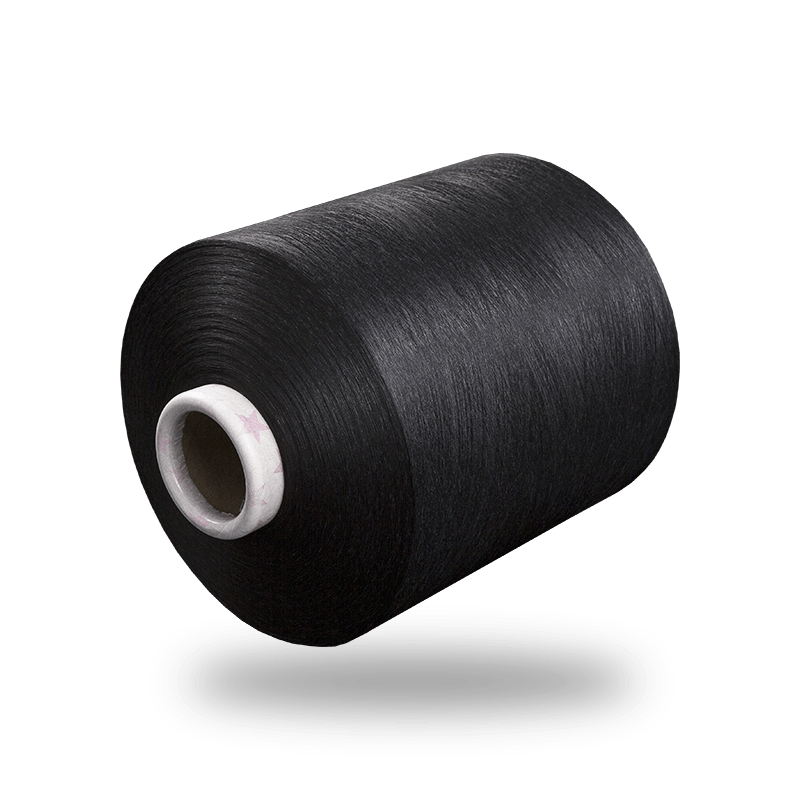

In the realm of textile innovation, where durability meets flexibility and aesthetics intertwine with functionality, Spandex Coated Wire emerges as a beacon of progress. This unique material, combining the resilience of nylon with the elasticity of spandex, has long been celebrated for its ability to elevate the performance and appearance of woven and knitted fabrics. However, the journey of Spandex Coated Wire doesn't halt at its current state; instead, it ventures boldly into the realm of advancements and innovations, paving the way for a future where textiles transcend conventional limitations.

At the forefront of Spandex Coated Wire's evolution lies a quest for enhanced durability and performance. Researchers and engineers are tirelessly exploring avenues to bolster its wear resistance, ensuring that it can withstand the rigors of even the most demanding applications. By delving into the intricacies of material science and engineering, they aim to fortify Spandex Coated Wire, empowering it to endure prolonged usage without compromising on quality or integrity.

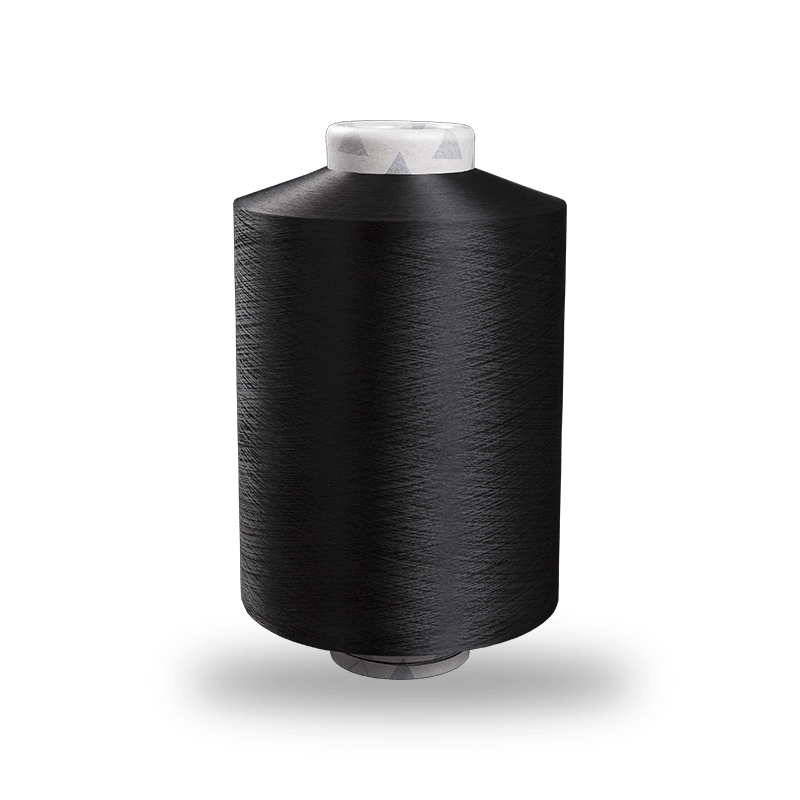

Simultaneously, efforts are underway to unlock new frontiers in elasticity. The elasticity of Spandex Coated Wire defines its versatility, enabling it to stretch and adapt to various shapes and movements seamlessly. Innovators are pushing the boundaries of elasticity, striving to enhance its stretchability and recovery properties. Through meticulous experimentation and refinement, they seek to imbue Spandex Coated Wire with unprecedented flexibility, opening doors to a myriad of novel applications across industries.

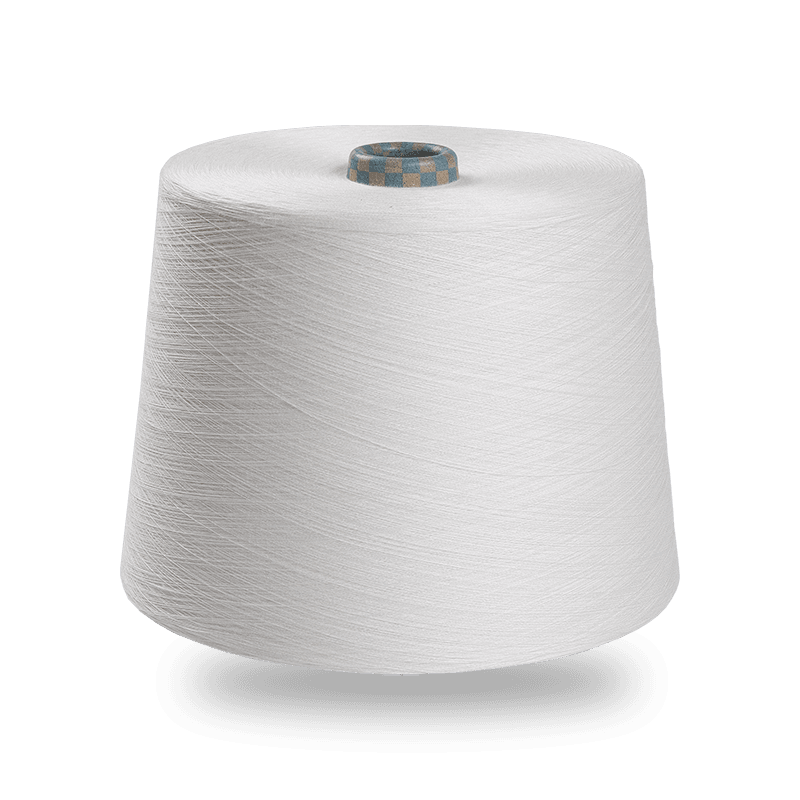

Sustainability stands as a cornerstone of modern innovation, and Spandex Coated Wire technology is no exception. As the world increasingly gravitates towards eco-conscious practices, researchers are pioneering sustainable solutions within the realm of textile production. Innovations in Spandex Coated Wire technology are aligned with this ethos, with a focus on reducing environmental impact throughout the manufacturing process. From utilizing recycled materials to implementing energy-efficient production techniques, strides are being made towards a more sustainable future for Spandex Coated Wire and the textiles it enhances.

Moreover, advancements extend beyond the realm of material properties to encompass manufacturing processes and functional capabilities. Innovators are exploring novel coating techniques that afford greater precision and control over the spandex application, resulting in enhanced consistency and quality of the final product. Additionally, research is underway to integrate functional additives into the spandex coating, endowing Spandex Coated Wire with supplementary functionalities such as antimicrobial properties or UV resistance.

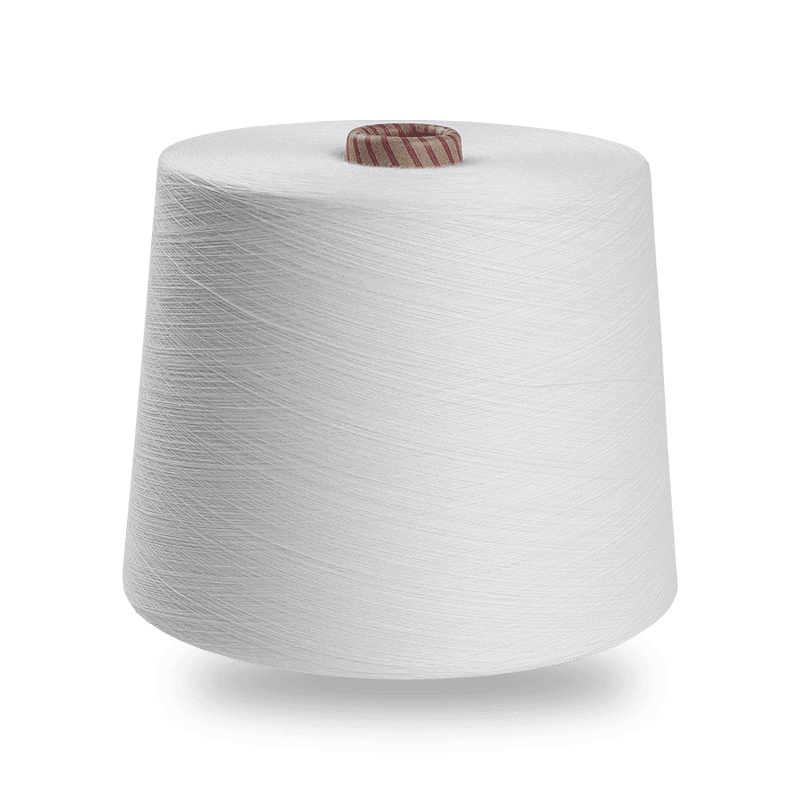

In the pursuit of innovation, customization and tailorability emerge as guiding principles. Researchers are developing methods to tailor Spandex Coated Wire to meet specific performance requirements and design preferences across diverse industries. Whether it's fine-tuning its properties for aerospace applications or infusing it with vibrant hues for fashion endeavors, the adaptability of Spandex Coated Wire knows no bounds.

Furthermore, the convergence of Spandex Coated Wire technology with the burgeoning field of smart textiles heralds a new era of possibilities. By integrating Spandex Coated Wire into smart textiles, researchers envision textiles that not only boast exceptional flexibility and durability but also harbor intelligent functionalities such as sensing and actuation. This symbiotic relationship between tradition and innovation propels Spandex Coated Wire into the realm of the future, where textiles transcend mere fabric and become conduits of technological advancement.

English

English 中文简体

中文简体 Español

Español عربى

عربى