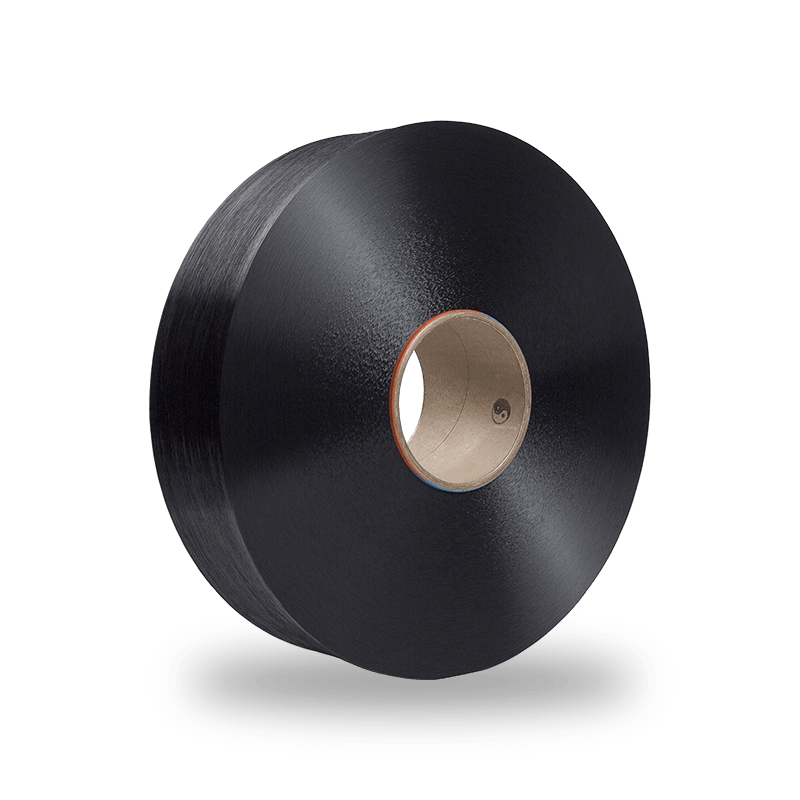

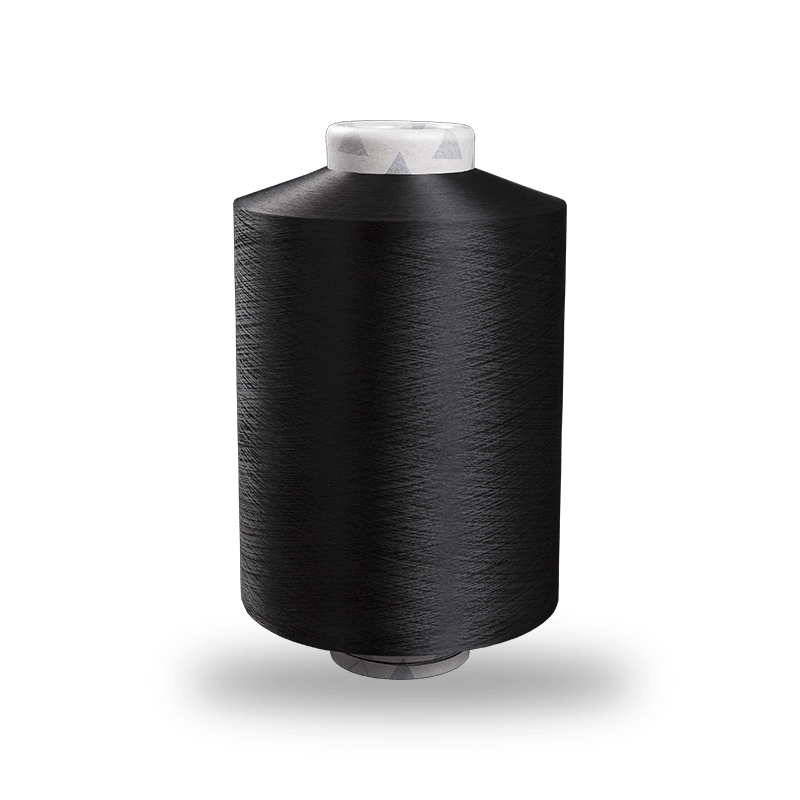

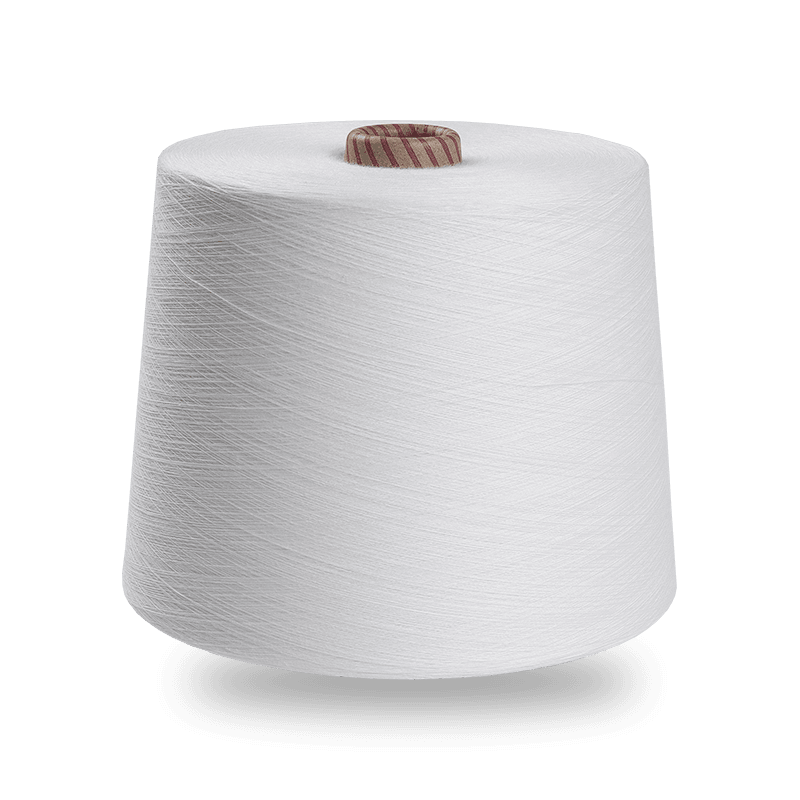

Nylon 6 FDY (Fully Drawn Yarn) is a high-performance synthetic fiber known for its excellent strength, elasticity, and durability, making it a popular choice in various textile applications. To maintain the exceptional qualities of Nylon 6 FDY, it is crucial to follow proper storage and handling procedures. The yarn’s performance can be significantly affected by environmental factors and physical handling, which necessitates adherence to best practices for preserving its integrity.

Firstly, Nylon 6 FDY should be stored in a dry, temperature-controlled environment. Excessive moisture can lead to issues such as yarn swelling or degradation, affecting its tensile strength and elasticity. It is essential to keep the yarn away from high humidity areas, which can cause the fibers to absorb moisture and potentially compromise their performance. Ideal storage conditions involve maintaining a temperature range between 15°C and 25°C (59°F to 77°F) with low relative humidity, typically around 65% or less. Utilizing dehumidifiers or climate-controlled storage facilities can help manage these conditions effectively.

In addition to controlling temperature and humidity, Nylon 6 FDY should be stored in a clean, dust-free environment. Dust and contaminants can adhere to the yarn, leading to potential issues during subsequent processing or use. It is advisable to store the yarn in its original packaging until it is ready for use, as this helps protect it from environmental pollutants. The yarn should also be kept away from direct sunlight, as UV radiation can weaken the fibers and cause color fading.

Proper handling practices are equally important to maintain the quality of Nylon 6 FDY. When moving or transporting the yarn, avoid any excessive friction or mechanical stress that could cause abrasion or deformation. Careful handling minimizes the risk of yarn breakage or defects. Additionally, if the yarn needs to be spooled or rewound, ensure that the equipment used is clean and well-maintained to prevent contamination or damage.

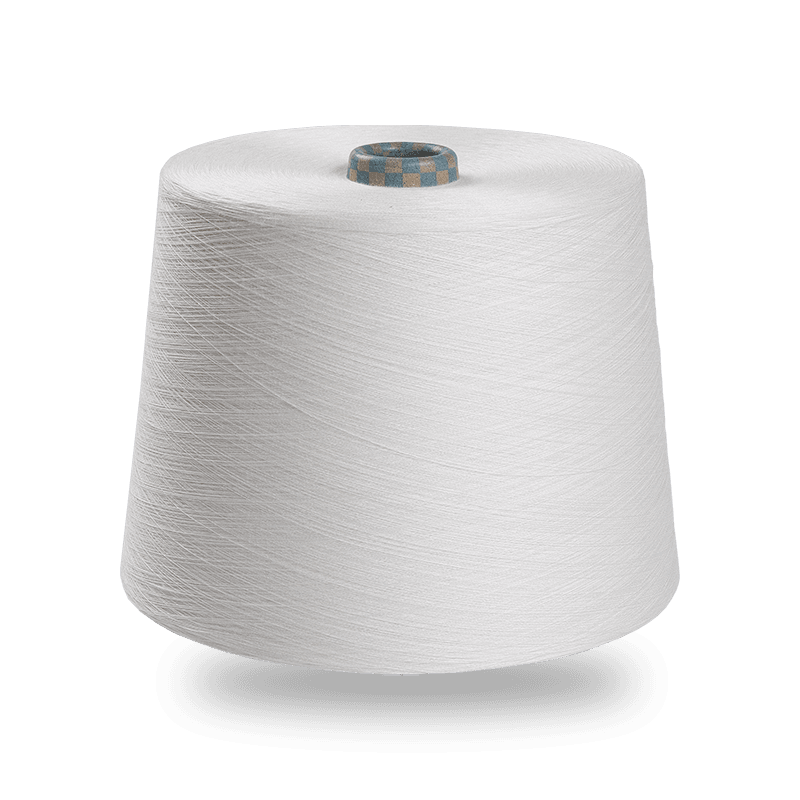

Integrating these practices with the use of high-quality yarns, such as Siro Spun yarn, can further enhance the overall quality of textile products. Siro Spun yarn, known for its advanced spinning technology, offers superior smoothness, strength, and durability compared to traditional spinning methods. Its unique double twist spinning process results in a yarn with high uniformity and less hairiness, contributing to enhanced fabric performance. By combining Nylon 6 FDY with Siro Spun yarn, manufacturers can achieve fabrics that not only retain their aesthetic and functional qualities but also benefit from the added advantages of advanced yarn technology.

Maintaining the quality of Nylon 6 FDY involves careful attention to storage conditions and handling practices. By ensuring that the yarn is stored in a dry, temperature-controlled, and clean environment, and by handling it with care, you can preserve its strength, elasticity, and overall performance. Combining these practices with the use of high-quality yarns like Siro Spun can further enhance the quality and longevity of textile products, ultimately leading to superior end-user satisfaction.

English

English 中文简体

中文简体 Español

Español عربى

عربى