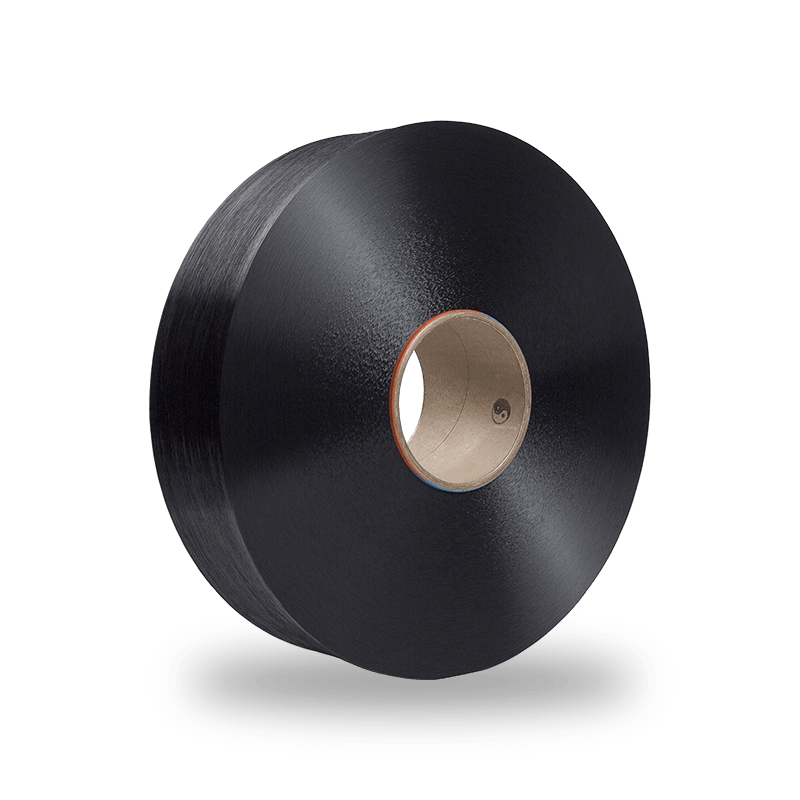

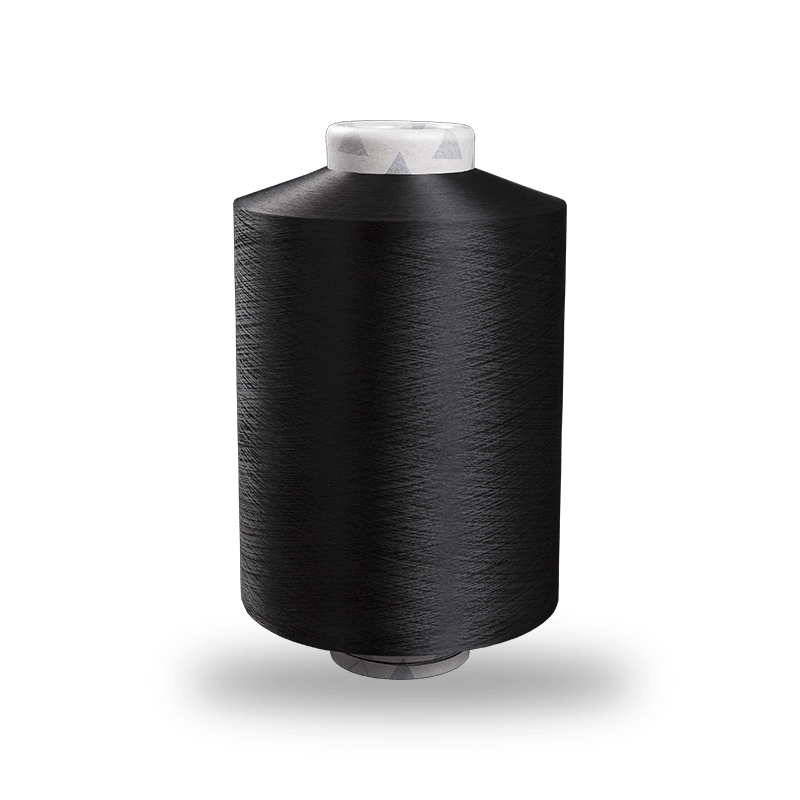

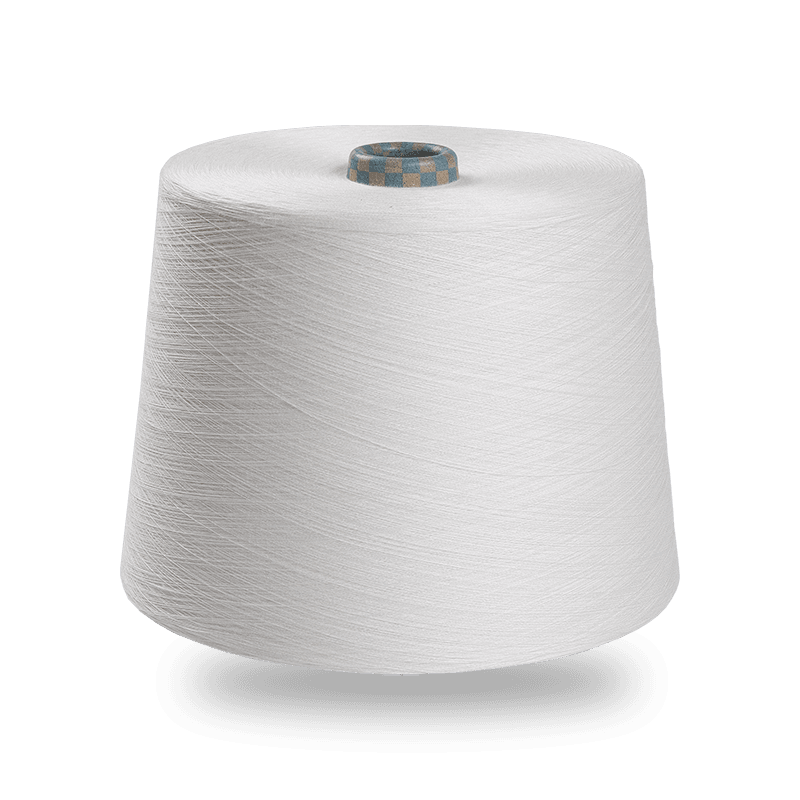

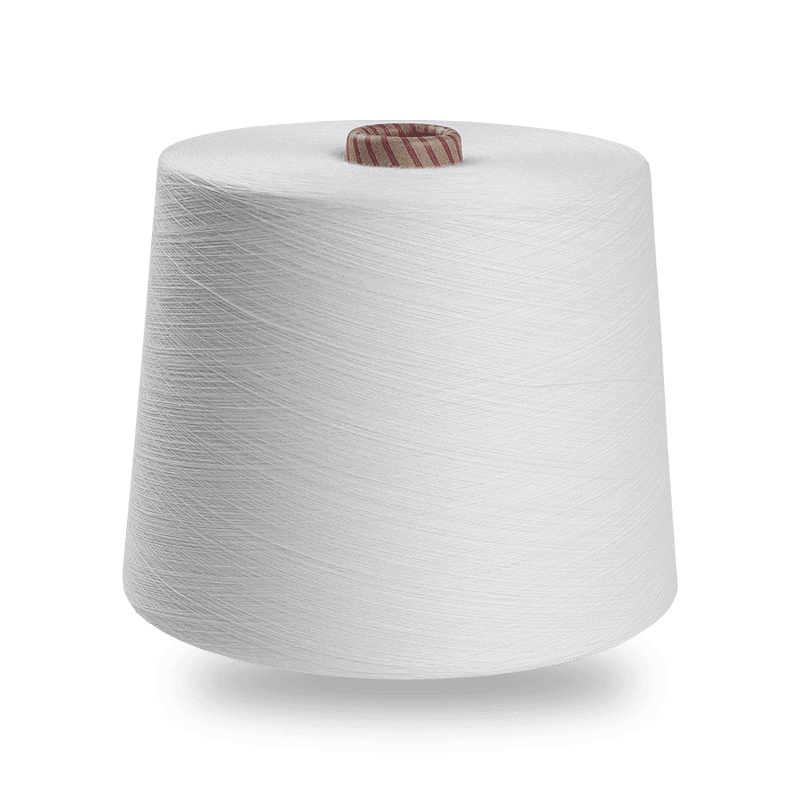

When it comes to maintaining the quality of Nylon 6 Fully Drawn Yarn (FDY), proper storage and handling are crucial. Nylon 6 FDY is a high-performance filament made through a sophisticated melt spinning process, resulting in a yarn that boasts stable quality, minimal wool breaks, and excellent dyeing uniformity. Its versatility makes it ideal for various applications, including warp and weft knitting, and it is widely used in the production of sportswear and sun protection clothing. However, to preserve these advantages and ensure the yarn performs optimally, specific care protocols must be followed.

Firstly, Nylon 6 FDY should be stored in a clean, dry environment. Moisture is the primary enemy of synthetic fibers, as it can lead to degradation and compromise the yarn's strength and elasticity. Therefore, the storage area must be kept free from excess humidity and moisture. Ideally, Nylon 6 FDY should be kept in sealed containers or packaging that protects it from environmental factors. Additionally, the storage temperature should be stable and moderate, avoiding extreme heat or cold, which can negatively affect the yarn's properties.

Handling Nylon 6 FDY requires careful attention to avoid physical damage. The yarn should be handled gently to prevent abrasion or fraying, which can occur if it comes into contact with rough surfaces or sharp edges. During transportation and handling, it's important to use protective coverings and avoid any actions that might cause mechanical stress or entanglement. For bulk storage, ensure that the yarn is not compressed or subjected to excessive weight, as this could lead to distortion or uneven tension, affecting the yarn's performance.

In terms of operational practices, it is advisable to work with Nylon 6 FDY in conditions that are as dust-free as possible. Dust and particulates can interfere with the dyeing and finishing processes, leading to inconsistent results. Regular cleaning of equipment and work areas will help maintain the yarn's quality throughout its lifecycle. For manufacturers and textile processors, following these protocols ensures that the high standards associated with Nylon 6 FDY—such as its stable quality and dyeing uniformity—are consistently met.

Proper storage and handling of Nylon 6 FDY are essential to maintaining the yarn's superior attributes. By keeping it in a controlled, moisture-free environment, handling it with care, and ensuring clean operational conditions, you can maximize the performance and longevity of this versatile and high-quality filament.

English

English 中文简体

中文简体 Español

Español عربى

عربى